Pulp molded inner packaging is a functional inner packaging material made from natural plant fibers (such as waste paper and sugarcane pulp) through processes like molding, compression molding, and drying. It is specifically designed to provide cushioning, shock absorption, and positioning protection for light industrial products.Moulded paper pulp packaging can effectively protect the safety of products in the process of transportation and storage, and meet the requirements of environmental protection at the same time, can replace the foam plastic molding packaging materials that cause white pollution. ?

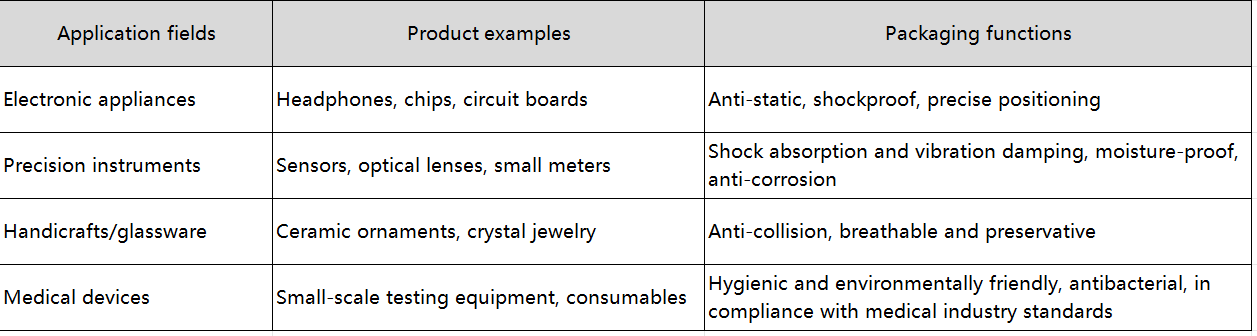

Its core advantage lies in the deep combination of life-cycle environmental protection and customized protection capability, which can not only meet the precision packaging needs of electronics, instruments, crafts and other products, but also respond to the global "plastic ban and plastic limit" policy to help enterprises realize green production transformation.

?

Pulp molded inner lining packaging, with its three core advantages of environmental friendliness, customization and high protection, is reshaping the lightweight industrial product packaging market. Whether it is an enterprise pursuing green transformation or a high-end product requiring precise protection, choosing pulp molded inner lining is not only a commitment to the environment but also a reliable guarantee for product safety.

?

1. Product Overview

Pulp molded inner lining packaging, with environmental protection at its core, integrates protection, customization and cost advantages, making it an ideal choice for lightweight industrial products to achieve green packaging upgrades.Its application in electronics, instruments, crafts and other fields can not only effectively reduce transportation losses, but also help enterprises practice the concept of sustainable development and improve brand competitiveness.

?

2. Product advantages

Environmentally friendly and sustainable

Moulded paper pulp packaging uses 100% recycled waste paper or bagasse and other natural plant fibers as raw materials. It complies with the ISO-14000 international environmental protection standard. It can be naturally degraded, avoiding white pollution. The production process is green and pollution-free, and the wastewater can be recycled.

?

Outstanding protective performance

Moulded paper pulp packaging has excellent cushion-proof, shockproof, compression, impact resistance, anti-static and anti-corrosion characteristics. Through the imitation design and elastic liner structure, it can closely fit the product, effectively absorb the impact force in transportation, and protect the light industrial products such as precision instruments and electronic equipment.

?

Customized design

Custom

Molded Pulp can be customized according to the product geometry, specifications and protection requirements. It supports multi-shape and multi-color design and is suitable for the positioning packaging needs of various lightweight industrial products, improving the fit between packaging and products.

?

Cost and efficiency advantages

The raw material source is sufficient, the production process is simple, the energy consumption is low, the product weight is light, the product can be stacked, the storage and transportation space and cost are reduced, and it is economical and practical.

?

3. Application scenarios