Pulp molded beverage packaging lining is an environmentally friendly lining product made of recycled pulp or natural plant fiber as raw material through molding and drying process, which is mainly used for the fixation and buffer protection of beverage bottles, cans and other containers.

?

The molded packaging production process relies on the fluidity and plasticity of pulp. Through molds, structures that fit the shape of containers are shaped. After drying, products with stable strength are formed, which have the core advantages of being degradable and renewable. It is an ideal choice to replace traditional plastic linings.

?

Pulp molded beverage packaging lining is gradually becoming the mainstream choice for sustainable packaging in the beverage industry due to its environmental protection properties, customization flexibility and performance reliability. Whether it is fast-moving consumer goods beverages or high-end gift sets, this product can achieve the dual value of "product protection + green marketing".

?

1. Product Overview

Pulp molded beverage packaging lining is a kind of environmentally friendly lining products made from recycled paper or natural plant fiber through molding process. It is mainly used for fixing and buffering beverage bottles, cans and other containers to provide effective protection in the process of transportation and storage.Its production process does not rely on oil resources excessively, and the product can be naturally degraded, which conforms to the global trend of sustainable development, and has become an important choice to replace the traditional plastic lining in the field of beverage packaging.

?

2. Core advantages

Environmental protection property outstanding

The raw material is recycled newspaper, kraft paper or sugarcane pulp and other renewable resources. The production process has low energy consumption and small pollution. The products can be completely degraded or recycled after being discarded, which effectively reduces the pollution of plastic packaging to the environment.

?

Strong buffer protection

Through the close combination of fiber structure and special process treatment, it has excellent seismic and anti-fall performance, can absorb the vibration and impact in the transportation process, and avoid the deformation or damage of the beverage container due to collision.

?

Breathability and customization

The material itself has certain air permeability, which can reduce the moisture accumulation inside the packaging. At the same time, it supports personalized design according to the shape and size of the beverage bottle/can to achieve accurate fit and improve the overall aesthetics of the packaging.

?

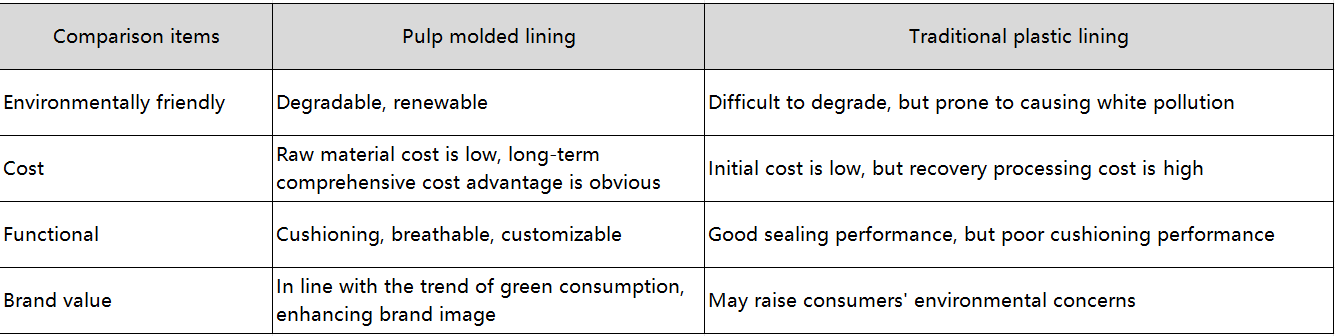

3. Comparative advantage