Pulp Molded Wine Shipper is a kind of natural plant fibers (such as bagasse, waste pulp, etc.) as raw materials, through the molding process customized environmental protection wine transport packaging products, designed for wine bottles and other fragile glass containers to provide buffer and shock protection.

?

The core advantage of custom molded

pulp packaging lies in the combination of

fully degradable environmental friendliness and precise protection. It can not only replace traditional plastic or foam packaging to

reduce environmental pollution, but also adapt to wine bottles of different specifications through structural design to meet the

anti-drop and anti-pressure requirements in transportation scenarios.

?

Pulp molded wine shippers are not only an innovation in packaging materials but also a key link in the construction of a "green supply chain" in the wine industry. It deeply integrates functionality, environmental friendliness and brand value, providing comprehensive solutions for alcohol enterprises ranging from transportation safety to the achievement of sustainable development goals.

?

Pulp molded wine shipper with environmental degradation, precise protection, cost control three core advantages, become the ideal choice for wine packaging green upgrade.With the tightening of global environmental protection policies and increasing consumer awareness of sustainability, its application potential in the field of high-end wine logistics and brand packaging will be further released.

?

1. Product Overview

Pulp molded wine Shipper is an environmentally friendly wine transport packaging product made of plant fibers (such as bagasse, waste pulp, etc.) through the molding process. It is designed for bottled wines such as wine, whiskey, brandy, and has the core advantages of cushion-shock, biodegradable, customized adaptation, and is widely used in logistics transportation, warehousing and retail display scenes.

?

2. Core advantages

Environmental performance: Green and sustainable throughout the entire life cycle

Degradable materials

The raw materials mainly use disposable bagasse, waste pulp and other renewable resources, and the products can be naturally degraded or recycled after use, effectively reducing the environmental pollution caused by traditional plastic packaging.

?

Resource recycling

No toxic emissions in the production process, in line with the EU REACH, the US FDA and other environmental standards, to meet the green packaging needs of high-end wine brands.

?

Protective performance: All-round protection for the safety of wine bottles

Buffering and shockproof structure

The three-dimensional honeycomb fiber structure formed by the molding process of pulp wine shipper can effectively absorb the impact and vibration during transportation, reduce the risk of bottle collision and damage, and is especially suitable for long-distance logistics.

?

Moisture-proof design

Some products can achieve moisture-proof functions by adding waterproof additives, preventing the wine body from being damaged due to changes in environmental humidity.

?

Customized design: Adapted to diverse scene requirements

Multi-specification adaptation

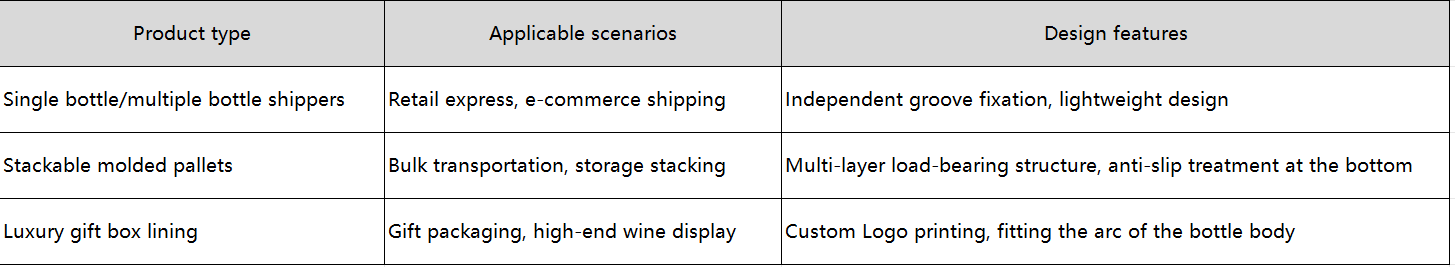

Custom

Molded Pulp packaging supports various specifications such as single bottle, 6pcs combination packaging, etc. The stackable pallet design saves storage space and meets the requirements of different transportation batches.

?

Brand value-added space

The surface of pulp wine shipper can be customized to print logos, brand information or retro classic patterns. It combines practicality and display, and is suitable for display in scenarios such as restaurant sideboards and villa wine cellars.

?

3. Product specification