Pulp molded electronic product protection plug-in is an environmentally friendly buffer lining customized from renewable fiber materials (such as recycled paper, bagasse, etc.) through the molding process, which is designed to provide comprehensive protection for electronic equipment during transportation and storage.

?

Its core advantage lies in the deep combination of environmental degradability and precise protection performance, which can not only replace the traditional plastic lining to solve the problem of white pollution, but also meet the protection needs of different electronic products such as shock and anti-static through structural design.

?

Pulp molded products are environmentally friendly packaging products made of waste paper, plant fiber and other renewable materials as raw materials through pulping, molding, drying, shaping and other processes. They are recommended by international environmental protection departments as an ideal substitute for foam plastics. They have core advantages such as full degradation, recyclability and low cost, and have become an important direction of green transformation of the global packaging industry.

?

pulp molding products with

environmental protection attributes, performance compatibility and cost advantages, has become the packaging industry "plastic reduction" of the first choice.Whether in

food, electronics or medical fields, its

customized design and life-cycle green features will help enterprises achieve sustainable development goals and respond to the upgrading of end-consumer demand for environmentally friendly products.

?

1. Product Overview

Pulp molded electronic product protection plug-in is a kind of plant fiber (such as waste pulp, sugarcane pulp, bamboo pulp, etc.) as raw materials, through the molding process made of environmental protection buffer packaging components, designed to provide electronic equipment in the process of transportation and storage shockproof, anti-static, compression protection.Its core advantages lie in full degradation environmental protection and precise adaptation, which can not only replace the traditional plastic foam lining to reduce environmental pollution, but also meet the protection needs of different electronic products through customized structure design.

?

2. Core performance

Buffer and shock

the three-dimensional structure formed by fiber interweaving can absorb external impact energy, effectively protect electronic equipment from collision damage, and the protection performance is better than traditional EPS foam.

?

Anti-static

The raw materials are naturally insulating, and no static electricity will be generated during the packaging process, avoiding the interference of static electricity on precision components such as chips and circuit boards.

?

Moisture-proof and anticorrosion

It can realize waterproof and moisture-proof function through process optimization to avoid short circuit or corrosion of electronic products in humid environment.

?

Precise adaptation

moulded pulp packaging supports customizing molds based on product size and shape to achieve a tight fit of "one product, one package" and reduce the shaking space during transportation.

?

Environmentally friendly and degradable

custom

pulp packaging is completely degradable within 45-90 days in the natural environment. It can be composted at home and leaves no plastic residue after disposal. It complies with environmental protection standards such as the EU RoHS and China's plastic ban order.

?

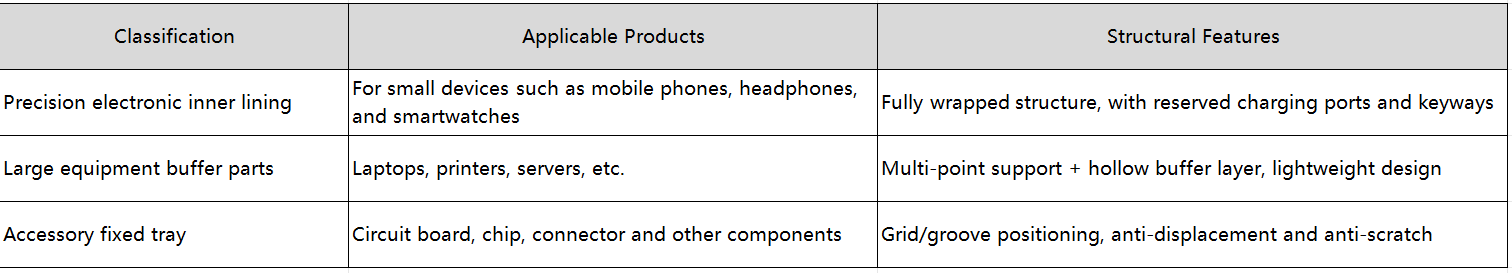

3. Applicable scenarios