Our

compliant Dangerous Goods Packaging (Dimensions :16.9x12.2x11.8 inches) is specially designed to

meet international standards for the transport of hazardous materials.Whether you are transporting

flammable materials, corrosive substances, toxic chemicals or reactive materials, our packaging can provide

strong protection and comply with relevant regulatory requirements.

?

The packaging is made of high strength corrugated material and offers excellent durability, impact resistance and leakage resistance. It is particularly suitable for industries such as chemical manufacturing, pharmaceuticals, oil and gas, and industrial logistics, where safe and compliant transportation is indispensable.

?

Each box is fully tested to comply with the UN certification standards, drop stack performance and strength requirement, ensure that your goods will reach the destination safe and legal.Its standard size has been optimized to achieve efficient stacking and container loading, thereby helping to reduce freight costs.

?

These solutions are suitable for export and domestic distribution and can be customized for hazard class, packaging group or inner container requirements.Choose our dangerous goods packaging to protect your brand reputation, ensure safe transportation throughout the supply chain, and comply with IATA, IMDG, and DOT packaging codes.

?

1. Product Overview

Dangerous goods carton packaging is a special packaging container designed for the transportation of dangerous goods. It has the core characteristics of corrosion resistance, leakage prevention, high strength and so on. It is suitable for the transportation and storage of chemical raw materials, dangerous chemicals, and some flammable/corrosive substances. Its production and design strictly follow international and domestic standards for dangerous goods packaging. Through material selection, structural optimization and compliance certification, it ensures the safety of dangerous goods throughout the entire logistics chain.

?

2. Core performance and technical features

Corrosion resistance and sealing property

With special coating or composite process, it can resist the erosion of acid, alkali and other corrosive dangerous goods, and prevent content leakage or external material pollution. Sealing designs (such as hot melt adhesive edge sealing and waterproof film lining) further enhance the leak-proof performance and are suitable for packaging liquid or semi-solid hazardous materials.

?

High strength and stability

Thickened corrugated cardboard (such as five-layer or seven-layer structure) and reinforced pulp materials are selected. The load-bearing capacity can reach 25-50 kilograms, with a compressive strength of ≥1500N, capable of withstanding vibration, collision and stacking pressure during transportation. Edge reinforcement treatments (such as metal edge banding and fiber tape) effectively prevent cracking.

?

Explosion-proof and buffer design

For flammable and explosive dangerous goods, built-in buffer layer (such as bubble film, pearl cotton) to absorb impact and reduce the risk of bursting;The box is reserved for pressure relief holes to balance the internal and external air pressure to avoid the expansion rupture caused by temperature changes.

?

3. Compliance mark

Mandatory warning signs

The box is printed with UN standard UN number, dangerous goods category symbol (such as flammable flame mark, corrosive mark), Chinese and English warning instructions and manufacturer information, in line with the requirements of the Globally Uniform System of Classification and Labelling of Chemicals (GHS)

?

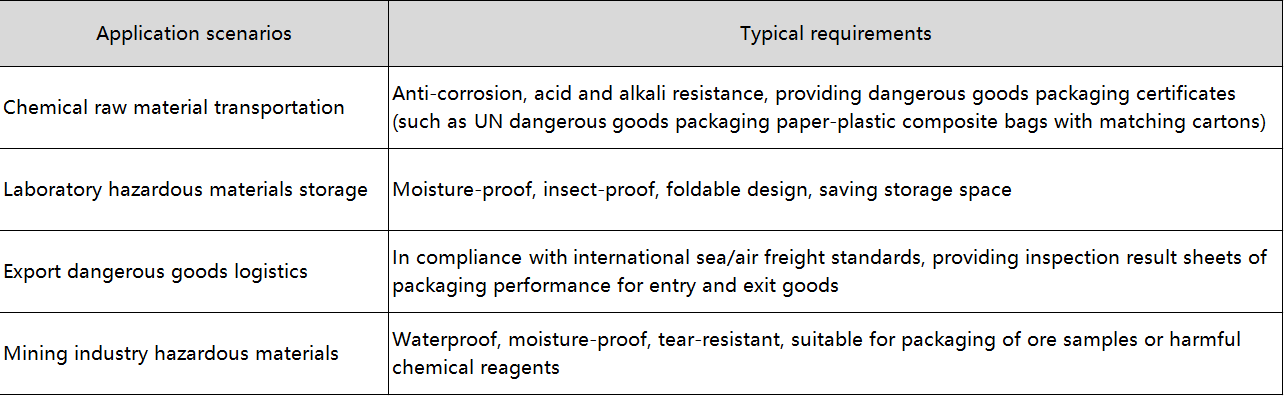

4. Applicable scenarios