Ensure

safe and compliant transportation through our "

Hazardous Materials Safe Packaging" (size :15.4x15.4x16.9 inches) specifically designed to

protect dangerous goods during storage and international transportation.The package design meets UN/DOT/IATA/IMDG standards for

Dangerous Goods Packaging.

?

The box is made of high strength corrugated material with high puncture resistance, compression resistance and environmental resistance. It is particularly suitable for industries handling flammable, corrosive or toxic materials, ensuring that the contents are protected from external impacts and preventing leakage.

?

The product is compatible with inner containers, VCI bags, and custom dividers, making it widely applicable in the chemical, pharmaceutical, and industrial logistics sectors.Whether you are looking for packaging for dangerous goods to be shipped, or need a certification solution to comply with export regulations, our boxes give you peace of mind and compliance.

?

Choose our hazardous materials to protect your next shipment from the risks of mishandling.

?

1. Product Overview

Dangerous goods carton packaging is a compliance packaging container designed for the transport of dangerous goods. It has the core characteristics of protection, sealing, customization and adaption, and is suitable for the transportation and storage requirements of some light dangerous goods (such as small electronic equipment, glass products, low risk chemicals, etc.).Its design strictly follows the United Nations Regulations for the International Transport of Dangerous Goods (TDG) and relevant domestic standards, through material selection, structural optimization and labeling specifications, to ensure the safety and environmental protection of dangerous goods in the whole logistics chain.

?

2. Core performance and technical features

Safety protection design

The reinforced five-layer Corrugated Board (such as AAA corrugated structure) and water-resistant kraft paper composite process, the paper gram weight ≥440gsm, hardness K≡B level, compressive strength ≥1500N, can withstand the vibration, impact and stacking pressure in the process of transportation.For flammable and explosive dangerous goods, can be customized flame retardant coating or lined with aluminum foil barrier layer, improve fire and barrier performance. ?

Sealing and leak-proof solutions

Equipped with dedicated sealing strips and hot melt adhesive edge sealing technology, combined with a waterproof PE film inner lining, it ensures that there is no leakage of liquids or volatile hazardous materials.For toxic and harmful substances, multi-layer composite barrier technology can be used to prevent the diffusion of toxic substances through packaging materials.

?

Compliance identification system

The outer packaging is printed with dangerous goods category identification (such as explosive and corrosive symbols), United Nations number (UN No.), gross weight, production date and operation warning signs such as "Up" and "Drop prevention" in accordance with GHS standards. The content is clear and durable, and complies with international transportation marking regulations.

?

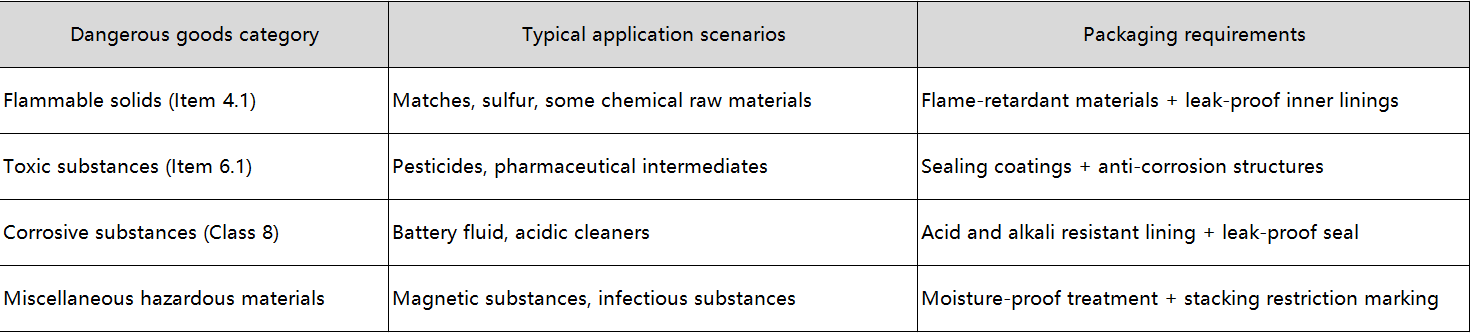

3. Scope of application