Our carefully designed "Safe Handling Hazardous Materials Packaging" (Dimensions :14.2x10.3x11.8 inches) is specifically designed to safely contain and transport controlled substances.This composite packaging for dangerous goods provides multiple layers of protection and ensures compliance with international safety standards such as UN/DOT/IMDG by combining the inner container with the outer container.

?

The sturdy shell structure is made of high-strength corrugated cardboard and can resist drops, punctures and compressions.On the inside, it is compatible with all kinds of liquid or solid dangerous goods containers, demonstrating excellent adaptability in chemical engineering, laboratory, pharmaceutical and industrial logistics.

?

The solution is ideal for companies that need to ensure both performance and compliance when it comes to hazardous material packaging.Whether shipping toxic, flammable or corrosive materials, the container ensures safe, stable and compliant packaging at every step of the supply chain.

?

If your business involves handling dangerous goods in packaging, this design is a reliable and scalable packaging solution that can reduce risks and improve operational efficiency.

?

1. Product Overview

Dangerous goods carton packaging is a compliance packaging container designed for holding and transporting dangerous goods with inflammable, explosive and toxic characteristics. It is produced according to the United Nations Recommendation on the Transport of Dangerous Goods (TDG) and relevant domestic standards. It has core functions such as protection, sealing and marking.It is widely used in air, sea and land transportation scenarios of category 2, category 3 and category 9 dangerous goods such as lithium batteries, chemicals and alcohol.The material is mainly high strength corrugated cardboard, and the special protection needs of different dangerous goods are met through customized structure design, while taking into account environmental protection and logistics adaptability.

?

2.? Core Features and Technical Advantages

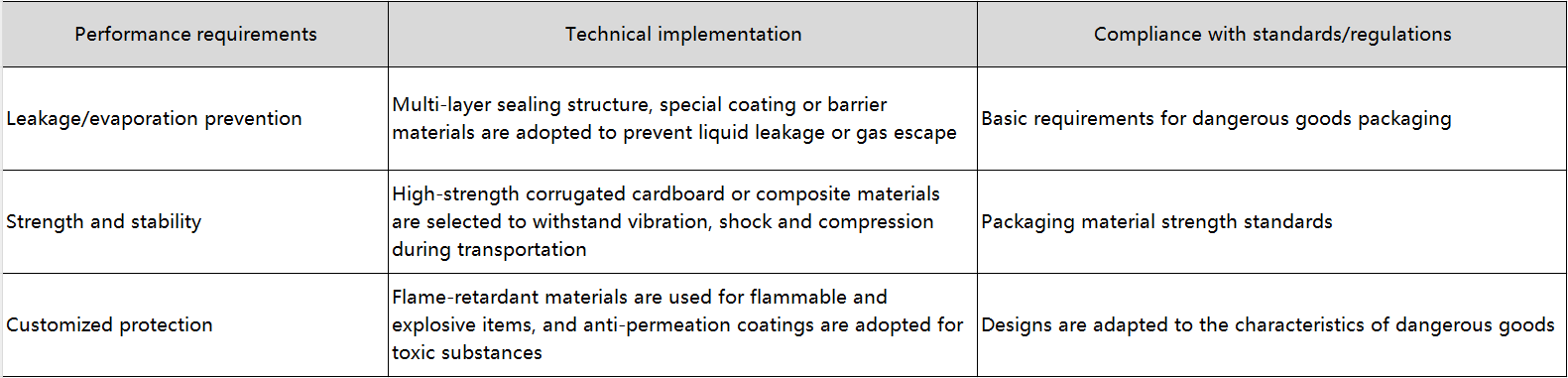

Safety protection performance

Sealing performance: It adopts a multi-layer corrugated structure and special sealing strips, combined with a leak-proof inner lining design, which can effectively prevent the leakage of liquid dangerous goods or the escape of gaseous volatile substances, and is suitable for volatile goods such as alcohol and electrolyte.

?

Compressive and breaking strength: The products are made of five or seven layers of thickened double corrugated cardboard. Some products are tested for bending strength and stacking capacity certified by CNAS to ensure no deformation or damage under the impact of transportation, stacking, loading and unloading.

?

Flame retardancy and chemical stability: For flammable materials, flame retardant coatings can be applied to the surface to delay the spread of fire.The material is made of acid and alkali resistant cardboard to avoid chemical reaction with dangerous goods and lead to packaging failure.

?

Compliance and Identification System

UN certification support: In accordance with the UN packaging standards, can provide UN performance single, dangerous package certificate and other documents, to meet the international transport declaration requirements of lithium battery (UN3480), flammable liquid (UN1263) and other dangerous goods.

?

Standardization of warning labels: Category of dangerous goods (such as "flammable liquid" and "corrosive substance"), UN number, safety warning icon and operation instructions printed on the box shall comply with GB12268 Name List of Dangerous Goods and IMDG code specifications.

?

Customization and environmental protection compatibility

Structure customization: According to the form of dangerous goods (liquid/solid) design leakproof tray, anti-pressure partition and other components;The size can be customized (such as 30×20×15cm to 120×80×60cm), suitable for small samples to large industrial parts packaging needs.

?

Environmentally friendly materials: Recyclable corrugated cardboard is adopted, and some products support reuse, reducing non-biodegradable waste and meeting the environmental protection requirements of modern logistics.

?

3. Product performance