Our

compliant Dangerous Goods Packaging (Dimensions :10.8x7.7x11.8 inches) has been meticulously designed to

meet international standards for the transportation of dangerous materials.These cases are made of

durable corrugated material and are ideal for the safe transport of

flammable, corrosive or toxic items.This dangerous goods container ensures that your goods are

properly protected and comply with relevant regulations at all times during the logistics process.

?

With its robust double-wall structure and customizable internal buffer layer, our dangerous goods containers perform exceptionally well in terms of impact resistance and environmental stress resistance.It is suitable for chemical, medical and industrial fields.Companies that need to ensure safe and compliant packaging of dangerous goods for air, sea or land transport rely on our products.

?

1. Product Overview

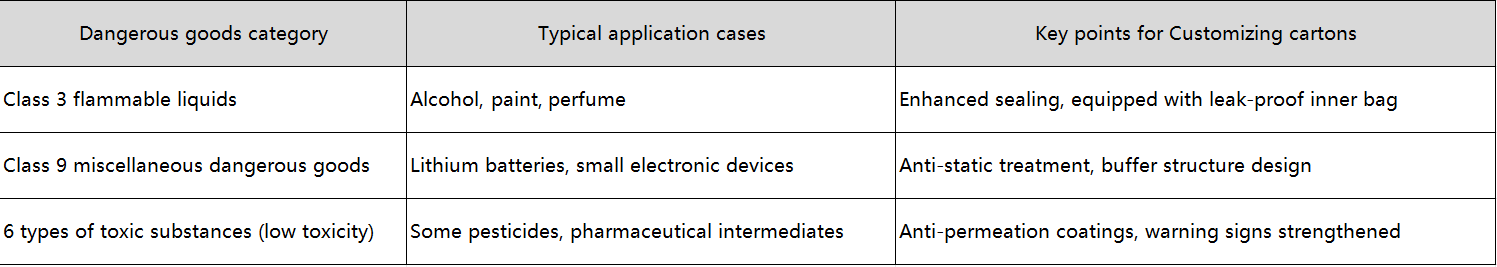

Dangerous goods carton packaging is a special transport container designed for dangerous goods with inflammable, explosive, corrosive, toxic and other characteristics. Through customized structure and material process, it ensures the safety and compliance of dangerous goods in the process of transportation and storage.The products are widely used in the air, sea and land transportation of chemical raw materials, fine chemicals, lithium batteries, laboratory chemicals and other dangerous goods within 9 categories, especially to meet the requirements of international transport standards for export dangerous goods.

?

2. Core Security Performance and Technical Features

Multiple protection designs ensure transportation safety

Corrosion resistance: By using specially treated pulp and cardboard or composite coatings, it can resist the erosion of corrosive hazardous materials such as acids and alkalis, preventing packaging damage and leakage.

?

Sealing leakage prevention: through multi-layer corrugated structure and special sealing strip design, it can realize double leakage prevention of liquid and gas dangerous goods, and adapt to volatile substances such as alcohol and electrolyte.

?

Strength and explosion-proof: Use five or more layers of thickened corrugated cardboard, some products integrated with metal explosion-proof lining, can withstand vibration, collision and pressure changes in the process of transportation, reduce the risk of bursting.

?

Compliance identification and tracking management

Warning label standardization: According to the international dangerous goods transport Code (such as IMDG Code) printing UN number, dangerous goods category symbols (such as flammable, corrosion marks) and operation warning, to ensure that transport personnel quickly identify the risk.

?

Traceability design: Support customized QR code, bar code or RFID tag, realize full link tracking from production to delivery, and facilitate logistics management and emergency traceability.

?

Customization and scene adaptation

Size and load-bearing customization: The box structure is designed according to the weight (25kg, 50lb, etc.) and form (solid, liquid, powder) of dangerous goods. The minimum order quantity is flexible to meet the needs of small batch trial operation.

?

Special scene reinforcement: for fragile dangerous goods (such as laboratory samples) to add buffer foam or shock insulation layer; We provide heat insulation linings for products in high-temperature environments, suitable for various scenarios such as sea and air transportation.

?

3. Applicable scenarios