Custom honeycomb panels (8"x60"x1.5") provide a

lightweight, environmentally friendly and impact-resistant packaging solution ideal for industrial applications.The

hexagonal honeycomb core structure provides excellent

compressive strength while significantly

reducing the overall material weight, thus reducing transportation costs. ?

With custom adhesive backing, our honeycomb panels are easy to install and can firmly adhere to various surfaces, thus eliminating the need for additional fasteners or tapes. They are particularly suitable for protective padding, pallet layer padding, internal packaging, or as spacers for fragile products during transportation and storage.

?

This product is made of recyclable kraft paper and reinforced with water-based adhesives, meeting modern sustainability requirements without compromising its performance. It can withstand pressure without being crushed and maintain stable buffering performance during long-term storage or transportation.

?

These cardboard honeycomb panels are widely used in the automotive, furniture, electronics and logistics industries.Whether used for product separation, corner protection or structural enhancement, our custom honeycomb packaging sheets provide cost-effective and high-performance protection to meet your supply chain needs.

?

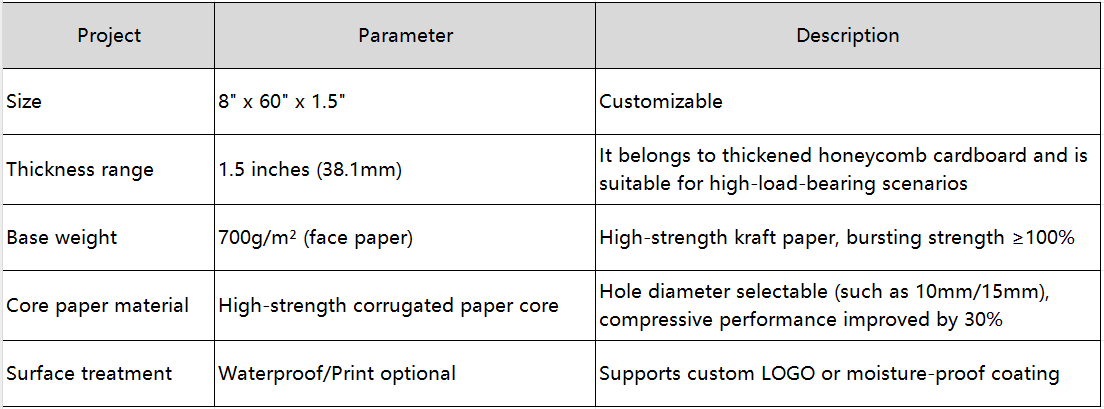

1. Product core parameter

Size specification

Single size: 8 inches (width) x 60 inches (length) x 1.5 inches (thickness)

Customizable length: Support for on-demand cutting (such as 24", 36" and other standard sizes)

Honeycomb structure: hexagonal aperture uniform, aperture diameter of about 0.5 inches, enhanced compression and lightweight.

?

Material and performance

Base material: High density honeycomb

paper core (kraft/recycled paper) or polypropylene (PP) plastic with outstanding water resistance and tear resistance.

Surface treatment: double-sided PET film + strong pressure-sensitive adhesive back adhesive, bonding strength ≥10N/cm2, support repeated peeling.

Physical characteristics: Density 0.3-0.5g/cm3, compressive strength ≥500kg/m2, suitable for dynamic load environment.

?

Applicable temperature and environment

Operating temperature: -20°C to +80°C (PP material up to 100°C).

Waterproof grade: IPX4 (paper base needs to be coated, PP material is more waterproof).

?

2. Specification parameters

?

3. Core application scenarios

Industrial packaging

Equipment cushioning: Cushioning gaskets for heavy machinery transport, replacing traditional foam.

Display stand: Temporary booth compartment or display board fixed, repeatable disassembly.

?

Architecture and decoration

Wall insulation: sandwich filling reduces noise transfer coefficient (STC≥35).

Temporary enclosure: construction area ground protective film to prevent equipment scratches.

?

Transportation

Compartment partition: partition inside the truck container to prevent cargo from sliding.

Ship deck: non-slip base material, suitable for wet environment.

?

4. Competitive advantage

Lightweight and load-bearing balance

Compared with solid sheet, the weight is reduced by more than 60%, but the load-bearing capacity is increased by 30%.

?

Environmental compliance

Paper-based products comply with ISO 14001 certification, with a recovery rate of 95%; PP material passed FDA food contact grade certification.

?

Ease of installation

Adhesive design supports non-nail fixing, and 50㎡ wall laying can be completed in 10 minutes.