Eco-friendly honeycomb board for packaging (24"x48"x3/4") provides a sustainable and high performance packaging solution for companies looking for durable protection and eco-friendly materials. These honeycomb composite panels are made of recycled kraft paper and are designed to provide maximum strength at an extremely light weight, making them highly suitable for applications such as protective padding, surface cushioning, and pallet stacking.

?

With its 3/4 inch

thick hexagon core layer structure, the

honeycomb cardboard on

the bearing capacity and

compression resistance,

shock absorption performance is superior to the traditional cardboard,

excels in structural stability.The

flat, smooth surface ensures compatibility with a wide range of packaging systems, while the standardized 24"x48" size makes it easy to integrate into production lines or custom cutting projects.

?

Commonly used in

Furniture Packaging, e-logistics and auto parts protection, these environmentally conscious

honeycomb paperboards are not only

cost effective but also

100% recyclable, in line with the latest trend in green supply chain management.

?

Upgrade your packaging with our heavy-duty, eco-friendly honeycomb cardboard sheets - an intelligent and sustainable solution to meet the demands of modern industry.

?

1. Specifications and structure

Dimension parameter

Panel size: 24 inches (W) x 48 inches (L)

Thickness: 3/4 inch (0.75 inch) double layer honeycomb construction for high rigidity and lightweight features.

Honeycomb core density: hexagonal honeycomb

paper core, core hole diameter is moderate, taking into account the compression and buffer performance.

?

Material property

Base material: high strength corrugated paper/kraft paper, surface coating treatment, moisture-proof, oil-proof.

Core material: Honeycomb paper core is made of recycled paper or raw pulp pressing, in line with environmental standards.

Weight: About 3-4 pounds per sheet, easy to handle and install.

?

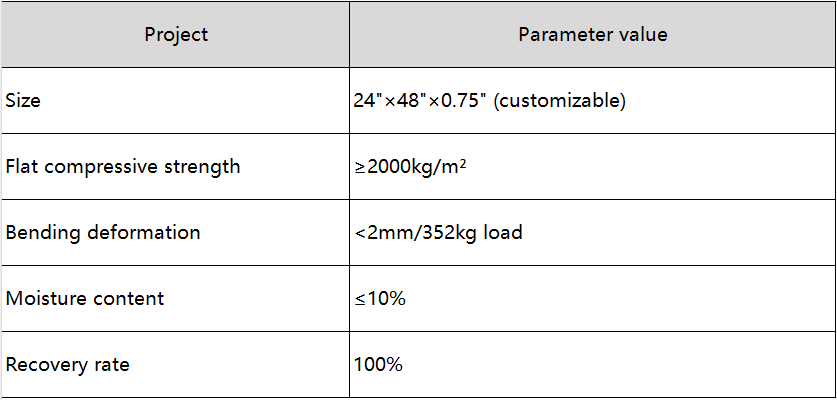

2. Technical parameters

3. Core advantages

Lightweight and high strength

Honeycomb structure through the mechanical dispersion principle, the unit weight carrying capacity is 3-5 times higher than the solid plate, suitable for heavy packaging or building template scenes.

?

Cushioning and sound insulation properties

The air layer of the honeycomb core can absorb impact energy and protect precision instruments or fragile products.

Sound insulation factor of 25-30 dB, suitable for soundproof wall, equipment compartment and other scenes.

?

Environmentally friendly and recyclable

100% biodegradable material that uses less energy to produce than plastic or sheet metal and meets international environmental certifications (e.g. FSC, ISO 14001).

?

4. Typical application scenarios

Industrial packaging

Heavy equipment transport liner (e.g. mechanical parts, glass products).

Mold lining or body protection in automotive manufacturing.

?

Architecture and decoration

Light partition wall, ceiling mezzanine of temporary building.

Booth structure or noise barrier in exhibition construction.

?

Logistics and warehousing

Shelf layer, tray lining, reduce the risk of sliding goods.

Insulation in cold chain transport (with insulation coating).