Our versatile honeycomb panels are ideal for packaging applications (48x92x1/2 inches), providing an excellent solution for protective, lightweight, and cost-effective packaging needs.The panels are made of kraft paper and are designed with hexagonal honeycomb construction, which provides an excellent strength-to-weight ratio, making them suitable for cushioning, void filling, layer isolation of pallets and protection of products during storage or transportation.

?

With extremely high compressive strength and excellent flatness, these honeycomb paperboard panels are ideal for dry industrial packaging, automotive components, electronic components, furniture, and more.The 1/2-inch thickness provides strong impact resistance while maintaining extremely low weight, which reduces shipping costs.

?

These boards are environmentally friendly and fully recyclable, making them an eco-friendly alternative to using foam and plastic as packaging materials. Their diversity is applicable to fields such as filling materials, padding and pallet stabilization. Whether you are a packaging supplier, distributor or an industrial customer seeking sustainable bulk packaging solutions, these honeycomb panels combine performance, value and sustainability. Just one panel can meet your needs.

?

The 48"x92"x1/2"

honeycomb cardboard adopts a

hexagonal honeycomb structure design, with

high-strength corrugated paper or

recycled polypropylene material as the core layer, and is covered with

kraft paper/polypropylene film on the surface, thus forming a?

lightweight and highly buffering composite?board. 1/2 inch thickness (12.7 mm) is suitable for

medium and heavy-duty packaging and construction requirements.?

1. Core strengths

Lightweight and high pressure resistance

The honeycomb structure can increase the load bearing per unit area by 3-5 times, and the density is only 1/6 of that of wood, reducing transportation costs.

Compressive strength ≥500kg/m2 (measured data), suitable for precision instruments, glass products and other fragile products packaging.

?

Environmentally friendly and recyclable

The material contains more than 70% recycled fiber or bio-based PP, meets the ISO 14001 environmental certification, and can be 100% recycled.

?

Multifunctional adaptation

Support laser cutting, die cutting grooves, can be customized special-shaped structures (such as holes, grooves) to meet special packaging needs.

?

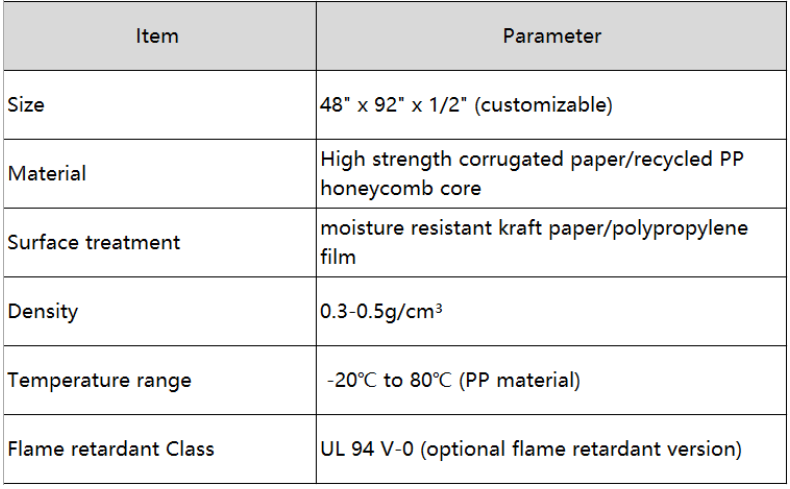

2. Technical parameters

?

3. Application scenario

Industrial packaging

Heavy equipment gaskets, cushioning trays for electronic components.

?

Architectural field

Temporary scaffolding panel, sound insulation layer filled.

?

transportation

Liner of truck cargo box, shockproof layer of shipping container.

?

Exhibition display

Lightweight booth construction, POP advertising backboard.