Continuous cardboard is a high-performance packaging material that is continuously processed and formed through an integrated production line. It features high production efficiency, stable structure, and strong customization capabilities, and is widely used in e-commerce logistics, home packaging, industrial protection and other fields. Its core advantage lies in breaking the traditional cardboard specification limitations, supporting on-demand cutting and personalized design, which can significantly reduce packaging costs and improve supply chain efficiency.

?

Foldable corrugated cardboard adopts a continuous production line process, which can simultaneously achieve raw material lamination, lamination, surface treatment and forming processing. The production efficiency is increased by more than 30% compared with traditional cardboard. Supports integrated customization to reduce the secondary processing costs for customers, especially suitable for the rapid delivery of bulk orders.

?

With the tightening of environmental protection policies and the increasing demand for lightweight packaging, continuous paperboard has a significant potential in the field of replacing plastics, wood and other materials. The global market size is expected to grow at an annual rate of 5% to 8%, with particularly prominent demand in the fields of e-commerce logistics and green packaging.

?

With the advantages of efficient production, flexible structure and sustainable environmental protection, continuous paperboard has become a key material in modern packaging and industrial fields. Its customization ability and wide applicability will promote the continuous innovation and development of the industry.

?

1. Product Overview

Continuous paperboard is a kind of multilayer composite paperboard material processed by continuous production line, which has three core advantages: stable structure, efficient production and flexible customization.Its raw materials are based on pulp and waste paper, which are made by fiber alignment, pressing, drying and other processes. It can be processed by surface coating, printing, folding and other processing according to needs, and is suitable for packaging, printing, industrial buffering and other scenes.

?

2. Product Features

Multi-layer composite structure

It is made of 2 or more layers of paper with different thickness or function. The outer layer optimizes the strength, the inner layer enhances the volume, the overall bending stiffness is high, and the groove creases can be directly opened. The processing performance is excellent.

?

Environmental protection and safety features

Using natural fiber raw materials, no glue bonding in the production process (molding by pressing process), does not contain heavy metals, alcohol and other harmful substances, in line with food contact material safety standards, part of the products can be recycled.

?

3. Product advantages

As a multifunctional packaging material, continuous paperboard has become an ideal alternative to traditional packaging materials through efficient production, structural innovation and environmental protection properties.In the future, with the growth of the global demand for sustainable packaging, its market potential in the field of heavy logistics and customized packaging will be further released.

?

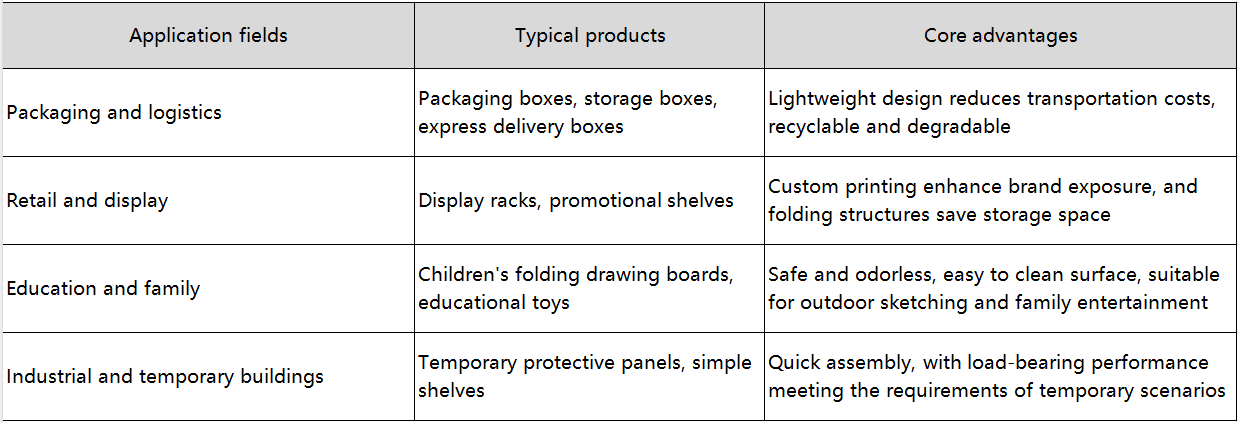

4. Application scenarios