Folding continuous cardboard is a kind of folding functional material made of corrugated or

thick cardboard as raw material through precise structure design and continuous production process. It has the core advantages of

continuous adjustable length and

on-demand cutting and molding, and is widely suitable for

customized packaging needs in

furniture, home appliances, e-commerce logistics and other fields. ?

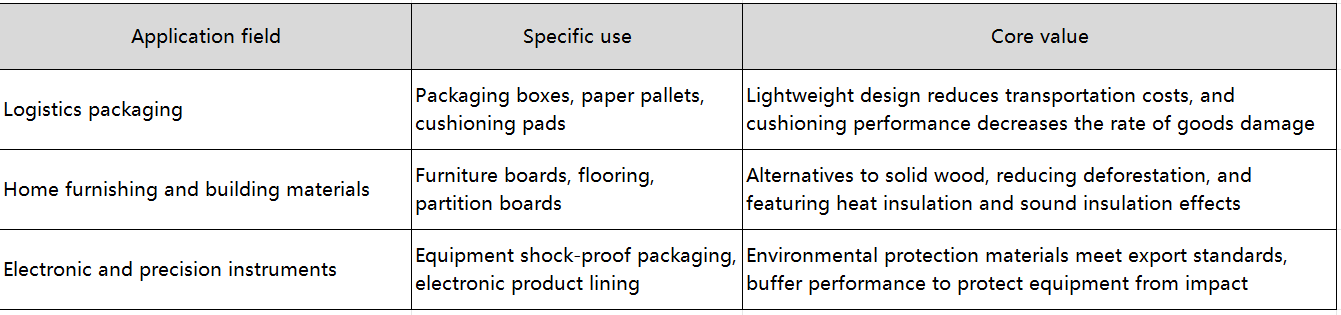

As an innovative form of corrugated outer packaging carton, continuous folding paperboard has widely covered the downstream industries of corrugated carton. The circulation of all items cannot do without packaging, so its downstream mainly includes communication information technology and electronics, office equipment, daily chemical products, light industrial products, and large household item packaging, etc.

?

Especially with the rapid development of the e-commerce industry after the epidemic, the demand for outer packaging cartons has risen sharply. Continuous folding cardboard, with its features of efficient customization and convenient transportation, can well meet the packaging needs of multiple varieties, small batches and fast turnover in e-commerce logistics.Whether it is the fine packaging of small electronic products or the overall protection of large furniture, continuous folding paperboard can provide suitable solutions through its flexible cutting and packaging.

?

Through material innovation, process optimization and scene adaptation, continuous folding paperboard provides a comprehensive solution of "high efficiency, environmental protection and low cost" for the modern packaging industry, which is an ideal choice to replace traditional packaging materials.

?

1. Product Overview

Continuous paperboard is a new type of corrugated paper material that combines infinite length cutting, wide customization and efficient molding technology. With multi-layer composite structure as the core, it has high strength and flexible processing characteristics, which is widely used in e-commerce logistics, home packaging, large object transportation and other fields.Through the optimization of pulp ratio and folding technology, the production process realizes the breakthrough of on-demand cutting, whole board transportation and diversified packaging forms, and effectively solves the pain points of the traditional carton industry with fixed specifications and low transportation efficiency.

?

2. Core Features and Advantages

Material structure and properties

It adopts a multi-layer composite process, with the outer layer being high-strength virgin fiber and the inner layer being lightweight recycled pulp. The weight range is 150-600 grams per square meter, featuring high bending stiffness and support for precise slotting and creasing. The surface can be treated with casting coatings, pigment coatings, etc., to meet the post-processing requirements such as printing and embossing, and is suitable for customized gift boxes, brand packaging and other scenarios.

?

Environmental protection attribute

The proportion of recycled pulp is up to 70%, 95% of the chemicals in the production process can be recycled, and 100% of the chemicals can be degraded after abandonment, which meets the European Union CE and domestic environmental protection standards.

?

Flexible customization and wide format advantages

The maximum width can reach 2500mm, which is at the leading level among similar domestic products. It supports free cutting according to product size without the need to change cartons of different specifications. The same workbench can complete the packaging of large items such as furniture and integrated kitchens, reducing material waste by more than 30%.

?

Transportation and storage optimization

With the whole board packaging design, the number of stacks during transportation is increased by 40% compared with traditional cartons. With the automatic cutting device, the pallet transfer can be realized, and the transportation efficiency can be increased by 25%, especially suitable for the rapid turnover demand of the peak period of e-commerce logistics.

?

3. Application scenarios