Continuous cardboard, also known as continuous folding cardboard, organ cardboard or corrugated folding cardboard, is a high strength packaging material made by multi-layer composite process. Its core advantages lie in uniform thickness, tight texture, high compressive strength, wear resistance and low deformation rate. The length can be freely cut according to requirements, making it suitable for customized packaging scenarios of large objects and irregular-shaped products. It is widely used in home furnishing, furniture, logistics transportation and other fields.

?

With high strength, flexibility and environmental protection as the core, continuous paperboard has become the key material of modern packaging industry through customized service and technological innovation.Whether it is home logistics or industrial manufacturing, its diverse application scenarios and sustainable attributes will help enterprises reduce costs and improve brand competitiveness, which is the preferred solution for future green packaging.

?

1. Product Overview

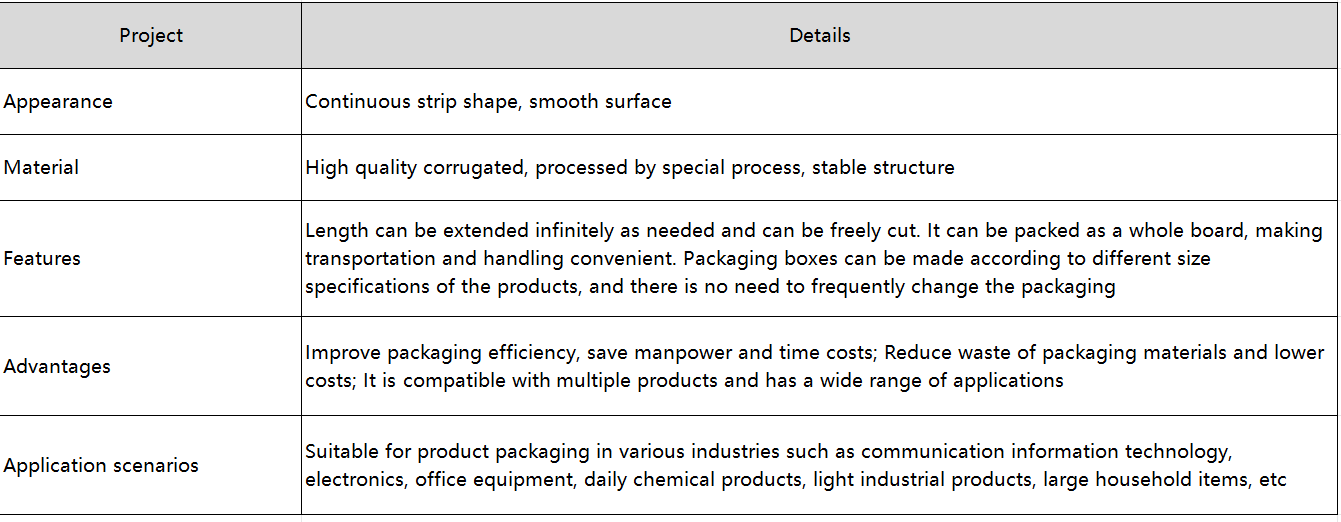

Continuous cardboard is an environmentally friendly type of board that is continuously formed through an automated production line and can be processed on demand. With its high strength, customizability and green sustainability, it is widely used in packaging, printing, logistics and other fields.

?

?

2. Core advantages

Flexible adaptability

It supports on-demand cutting length and shape to meet the packaging needs of communication electronics, daily chemical industry, household and other industries, especially suitable for the packaging scene of irregular items in e-commerce logistics.

?

Efficient production design

The integrated packaging process can be realized through continuous folding technology, combined with automatic blanking device, which can improve the amount of single stacking and solve the transportation efficiency problem caused by the space height limitation of traditional equipment.

?

Material and transportation optimization

It adopts a high-strength corrugated structure and has the performance of withstanding pressure and impact.The whole plate transportation reduces the loss of packaging materials, and reduces the logistics cost with forklift handling.