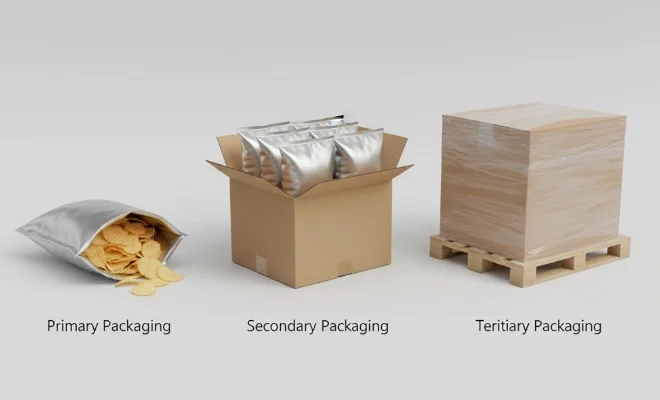

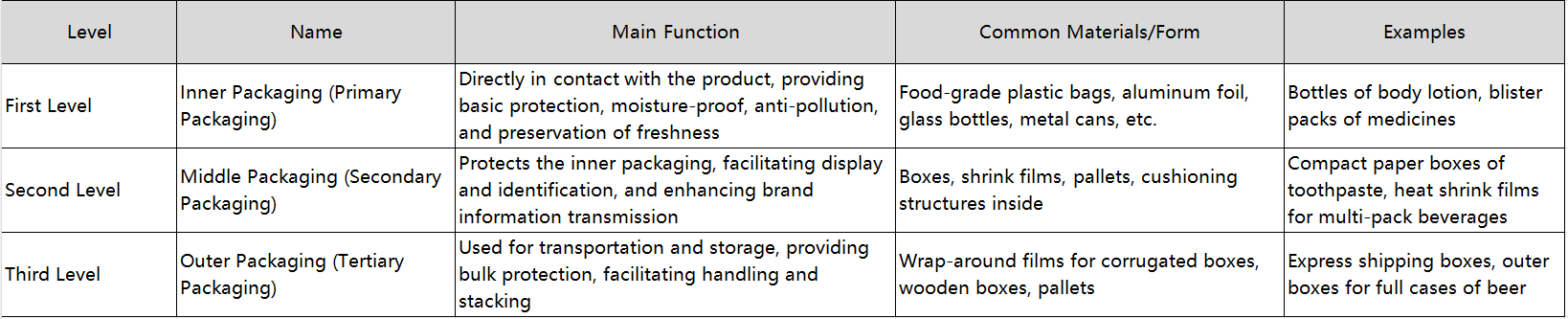

Product packaging "three layer structure" is a systematic design method, through hierarchical protection to ensure that products in the process of transportation, storage and sales integrity and attractive. This structure not only improves the user experience, but also meets the needs of environmental protection and cost control. In recent years, in order to curb excessive packaging, the state has also clearly limited the number of packaging layers for some commodities (such as tea) to no more than three layers.?

?

Product packaging is divided into three layers, it is in order to achieve the division of functions and overlay protection. With the expansion of commodity circulation and the improvement of consumers' quality requirements, single packaging has been unable to meet the multiple needs of moisture-proof, damage prevention and information transmission. Therefore, industry widely used "from the inside out" three levels of logic design, ensure the safety of the product whole process from production to consumption and beautiful.?

?

?

Tertiary Packaging

Tertiary packaging is the outer protective packaging in logistics transportation, mainly used for security secondary packaging and internal product safety in long distance transportation and storage process.?

?

In the entire supply chain of goods from production to consumers' hands, packaging is divided into several levels, each level has its specific function. Of these, "tertiary packaging" is the outermost layer, which does not directly touch the product or be displayed to consumers. Instead, it is industrial-grade packaging designed for efficient transportation, stacking and protection.?

?

It is commonly used for the export of large volumes of goods, e-commerce logistics or the transportation of heavy equipment to ensure that products can safely reach distribution centers or retail terminals.?

?

The core characteristics and functions of the third-level packaging

Positioning: Located outside the primary and secondary packaging, it is the outermost shipping packaging.

Main functions:

- Resist physical shocks such as vibration, extrusion and drop during transportation;

- Preventing moisture, dust, and theft;

- Improve loading and unloading efficiency (such as support forklift four-way fork);

- Realize pallet and containerization transportation.?

?

Common Materials and Structures

According to the product weight, transportation distance and environmental conditions, tertiary packaging can choose different materials:?

Light duty goods: corrugated carton + plastic tray + wrap film

Heavy/precision instruments: Plywood pallets, wooden cases, metal frames

Special requirements: Anti-static materials, temperature-controlled boxes, GPS tracking labels?

?

Three-level packaging is a key link to ensure the safe delivery of products in the complex logistics link. Although it is not seen by consumers, it greatly affects the transportation cost, damage rate and customer satisfaction. To choose the appropriate three-level packaging scheme, it is necessary to comprehensively consider the product characteristics, transportation mode and storage conditions.?

?

?

Secondary packaging

The secondary packaging is used for grouping multiple primary packaging unit, mainly in the service of transport and warehousing link the middle layer of packaging, usually don't directly to the consumer.?

?

In the process of product from production to sales, direct contact with the primary packaging of goods is not enough to meet the needs of mass transportation and storage management. Therefore, an additional layer of structure is needed to integrate small units of products, enhance logistics efficiency and provide supplementary protection - this is the core function of secondary packaging.?

?

Functions and Features

Integrated SKU: Combine multiple primary packages into a single Stock Keeping Unit for easy management and tracking.

Auxiliary transportation: As a collection container for small items, it is particularly important in e-commerce and retail distribution.

Enhanced protection: Provides additional cushioning for primary packaging to prevent extrusion or damage during transportation.

The terminal: Generally by retailers or warehouse personnel and dismantling, consumers rarely come into contact with directly.?

?

The nature of the secondary packaging is the bridge linking production and distribution, it is not the pursuit of beautiful and marketing, focusing instead on practicability, maneuverability and logistics cost optimization. While consumers can't see, but it is very important for the efficient operation of the entire commodity circulation system.?

?

Primary Packaging

Primary packaging is the first layer of packaging that comes into direct contact with the product, mainly serving to protect, preserve and display, and is usually used as the unit directly by consumers.?

?

Primary Packaging plays an important role in commodity circulation. It is not only the first "coat" of a product after it leaves the factory, but also directly affects consumers' usage experience and brand impression. According to several industry data, this type of packaging is widely used in food, medicine, cosmetics and daily necessities and other fields.?

?

The core characteristics of primary packaging

Direct contact with the product: This is the key to judge whether it is primary packaging standards, such as direct contact with the bottle of liquid beverage bottle.

Strong protective function: It prevents contamination, oxidation, leakage or physical damage, ensuring stable product quality.

Easy for consumers to use: The design often considers the opening of convenience, dose control and other human factors.

Information and marketing carriers: Labels are printed with ingredients, shelf life, brand identity and other information to help promote sales.?

?

Primary packaging is the first barrier between the product and the outside world, protection, storage, information transfer and brand display four big functions. It is the most direct contact with the part of the consumers, so the material selection, structure design and visual presentation requires careful consideration.?

?

?

The inner package is the "protection", the middle package is stronger than the "integration", the outer package is better than the "carrier". This layered model can not only effectively protect the products but also meet the requirements of different stages from production to consumption. Especially in the current highly concerned field of environmental materials and sustainable solutions, optimizing the three-layer structure (such as using degradable inner bags and FSC? certified paper boxes) has become an important direction for brand upgrading.?

?

Three layers of packaging structure through collaboration from the individual protection to the complete coverage of batch transportation, can not only guarantee the quality of the products, and to optimize supply chain efficiency. With the increasingly strict environmental protection regulations, the reasonable design of packaging levels has become a key link for enterprises to comply with regulations and achieve sustainable development.