As an innovative product in the field of sustainable packaging, paper food pallet is reshaping the industry standard of food storage, transportation and display with its core advantages of degradable materials, enhanced functional design and full scene adaptability. It integrates environmental protection concepts with practical needs, making it an ideal alternative to traditional plastic pallets, especially suitable for food fields such as fresh produce, baking, and takeout.

?

disposable paper food trays is an innovative product in the field of food packaging in recent years. It has become an ideal packaging scheme for

fresh, fruits, pastries and other foods with environmental protection materials, practical design and wide applicability.It combines the functionality of traditional pallets with the modern concept of environmental protection, showing significant advantages in

material safety, display effect and sustainable development. ?

In the context of global environmental awareness, paper food trays are made of renewable resources, with low carbon emissions in the production process, and can be recycled and reused after abandonment to reduce plastic pollution. Its promotion and application can help the food industry achieve the "carbon reduction" goal in the packaging process, meet consumers' demands for green products, and is an important choice for enterprises to fulfill their social responsibilities.

?

Disposable paper food trays redefines the practicality and environmental friendliness of food packaging through eco-friendly materials, innovative design and multi-functional adaptation.Whether it is to improve the terminal display effect, reduce logistics costs, or respond to the call for sustainable development, it has shown significant advantages and become a key product for the food industry to transform from "functional packaging" to "green packaging".

?

1. Product Overview

Paper food and snack trays, with food-grade materials, customized designs and environmental protection attributes as their core advantages, are widely used in scenarios such as snacks, fast food and baking. They can not only ensure food hygiene and safety, but also enhance user experience through flexible design. They are an ideal choice to replace traditional plastic trays.

?

2. Core material and process characteristics

Food-grade safe material

Environmentally friendly paper-based material

Select 300-350g kraft paper or art paper. Some products are made with PE lamination or plastic-free eco-friendly processes, featuring both oil-proof and water-proof properties. They are suitable for holding oily or juicy foods such as fried chicken, French fries, and barbecues, preventing leakage and contamination.

?

Degradable property

100% biodegradable paper material, odorless, no fumigation required, meeting the quarantine requirements for export packaging and the trend of environmentally friendly consumption. It can be naturally decomposed or recycled after use.

?

Structural and design highlights

Multiple specifications capacity selection

We offer a variety of sizes and capacities, such as approximately 250 milliliters on a No. 5 tray and about 750 milliliters on a No. 1 tray, to meet the needs of different snack sizes.Some products support a double compartment design, which can separate different types of food (such as snacks and dips).

?

Lightweight and portability

It is lightweight and easy to fold, saving transportation and storage space. It is especially suitable for scenarios such as takeout packaging, food exhibitions and tastings, and street snacks, enhancing the convenience of use.

?

3. Customized services

Flexible customized solutions

Size and printing customization

Supports adjusting the inner diameter, outer diameter and height of the pallet according to requirements. Brand logos, promotional slogans or patterns can be printed in full color to enhance brand recognition.For example, the use of coated paper, art paper material to achieve matte, gold foil and other special process effects.

?

Special function processing

We offer customized services such as PE lamination and oil-proof coating to enhance water and oil resistance.

?

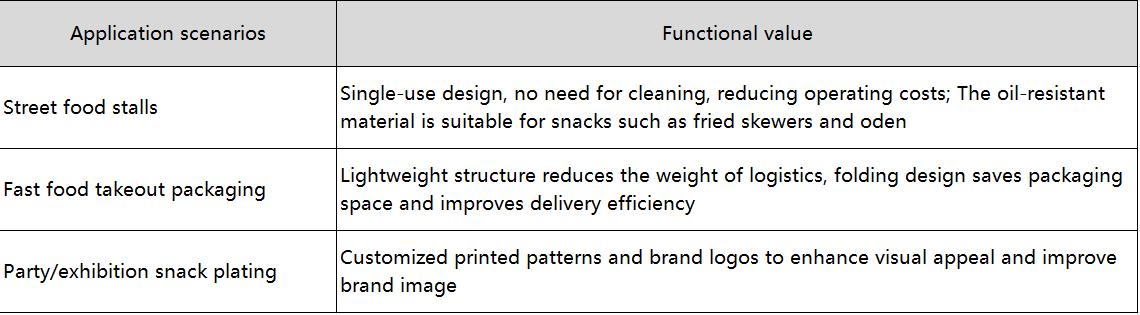

4. Application scenarios