Carton printing not only bears the protection function, but also increasingly becomes an important carrier of brand communication and consumer experience. With the rise of e-commerce and the emergence of personalized demands, traditional plate-making techniques (offset printing/offset flexography/gravure printing) and non-plate digital printing techniques (inkjet printing) have formed a complementary pattern. Different technologies have significant differences in cost, speed, accuracy, environmental protection and batch adaptability, which should be selected according to the actual order characteristics.?

?

?

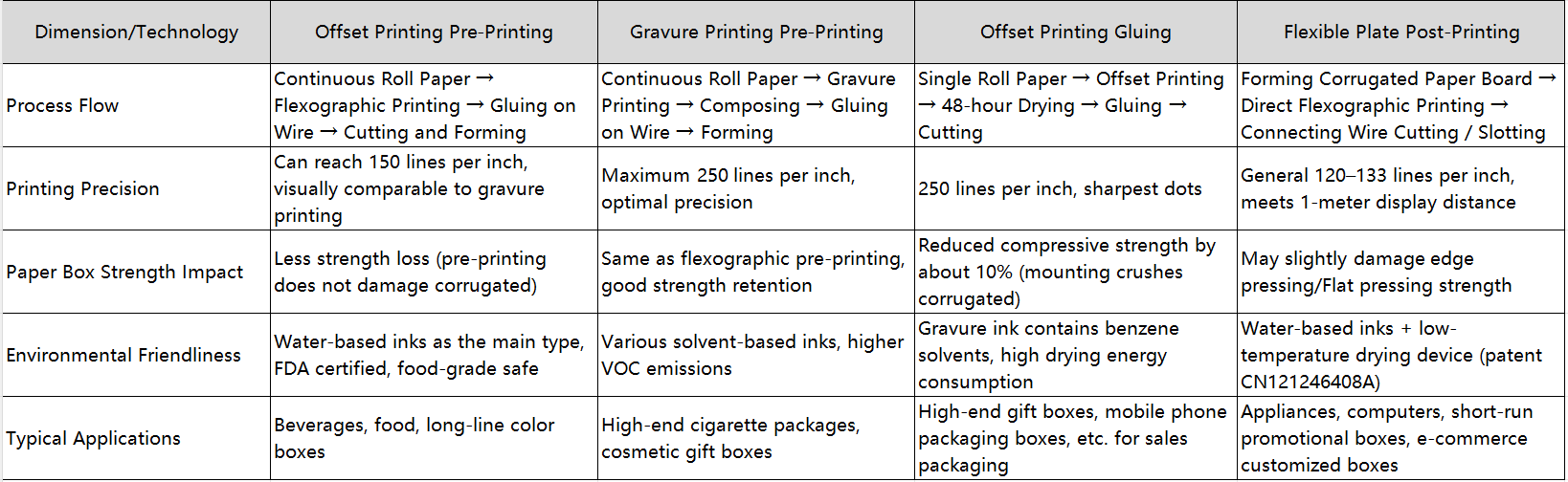

Comparison and Analysis of Four Main Technologies

Flexographic Printing

It is the main process of mass production of corrugated carton at present, especially suitable for medium and large batch pre-printing or direct printing.

It adopts flexible resin plate + anilox roller ink transfer, which is light in pressure and has little impact on corrugation strength. It can complete printing - slitting - creasing - die-cutting online.

Advantages: Water-based ink environmental protection, low cost, large size (up to 2.8m), suitable for linkage production line;

Disadvantages: The screen count is only 35 to 65 lines per inch, and the four-color image performance is weaker than that of offset printing.

Typical applications: Express packaging boxes, e-commerce logistics boxes, food outer boxes, etc.?

?

Offset printing

This is an indirect printing method. The paper surface is printed first, then a

Corrugated Board is attached. It is suitable for high-precision sales packaging.

Using the principle of oil and water insolubility, the PS version has high resolution (150-200 lines/inch), which can perfectly restore gradient, dot and spot color.

Advantages: Fine printing, accurate color reproduction, and capable of lamination /UV coating.

Disadvantages: Requires flat surface paper, cannot directly print corrugated, high cost, and low efficiency.

Typical applications: Premium gift boxes, high-end wine/cosmetics color boxes.?

?

Gravure Printing

The graphics and text are engraved in the recesses of the metal roller. The ink layer is thick, the luster is strong, and the durability is high. It is a highly stable and large-scale process.

Plastic film gravure printing + lamination (such as "plastic gravure printing composite carton") or coated paper gravure printing + lamination can both achieve visual effects comparable to offset printing.

Advantages: Full ink, strong sense of layering, not easy to color;

Disadvantages: High plate-making cost, long production cycle, and difficult modification. It is only suitable for stable mass production orders.

Typical applications: Whole-box packaging for brand fast-moving consumer goods, and export high-standard cartons.?

?

Digital inkjet printing

Without plates, variable data, one print job starts, it is a breakthrough technology for addressing small batch, rapid response, and customized demands.

It adopts water-based /UV inkjet and supports Onepass high-speed mode (for large volumes) and scanning high-precision mode (for full pages/large sizes).

Advantages: Zero plate-making fee, short delivery time (within 24 hours), support for personalization (such as customer name, QR code, dynamic information), low-carbon and environmentally friendly;

Disadvantage: The cost per sheet is slightly higher than that of traditional large-scale flexographic printing.

Typical applications: Sample proofing, holiday limited edition, B2B customized boxes, rapid SKU iteration for e-commerce.?

?

Recommendations for the Use of Four Printing Technologies for Carton Packaging

The term "four" does not refer to an absolute classification. Instead, it is a combination of the most representative technologies that have been summarized in the industry practice based on their processing paths and application maturity.?

?

Flexographic printing technology

This technology combines the advantages of various printing processes. It has a light printing pressure, thick ink, clear prints, and a high plate reusability rate. It has strong adaptability to printing materials. It can print cardboard with rough surface or good gloss, and can also print absorbent or non-absorbent materials. Whether it's a fine screen plate, line plate, spot color line plate, or solid area plate, it can handle the job. If you need medium or large-scale printing, especially for cartons with complex patterns, flexographic printing is a great choice. It has relatively low costs and fast printing speed.?

?

?

Offset Printing Technology

Offset printing is first printed on the surface paper and then pasted onto corrugated cardboard, making it suitable for high-end cartons. It features high dot resolution, rich printing gradation, soft tones, convenient plate production and relatively low cost. If you need to print color pre-printed paper for cartons, such as fine line plates and multi-color screen plates, offset printing is very suitable. However, it is not very suitable for large-scale printing. The cost is relatively high and the printing speed is not fast either.?

?

?

Gravure Printing Technology

The printing plates of gravure printing have a high durability, fast printing speed, thick ink layer, rich ink color with a three-dimensional effect, and fast drying speed. For large-area and thick ink printing products, such as solid and spot color lines and fine screen patterns, gravure printing is a good choice. But its plate-making process is complex, the cost is high, and the operation of changing the plate is troublesome, so it is more suitable for mass printing.?

?

?

Digital Printing Technology

Digital printing can achieve immediate printing, has a short production cycle, and its efficiency is about 50% higher than that of traditional printing. It can also be printed on demand and in a personalized manner, making it suitable for small-batch and customized needs. If you need quick delivery or have the demand for variable data printing, digital printing is very suitable. However, its printing cost is relatively high and it is not very suitable for large-scale printing.?

?

?

?

Flexographic printing is currently the mainstream choice for carton packaging printing, especially suitable for the production of corrugated cartons in large quantities, with high efficiency and high environmental protection requirements. And digital printing is rapidly rising as the core solution of small batch, personalized, quick reverse order; Offset printing focuses on high-grade color cardboard boxes, but it needs to be preprinted + mounted, and the process is more complex.?

?

How to Choose the Appropriate Packaging Printing Technology�?

- Consider the printing effect: The visual effects presented by different printing techniques vary greatly. If you pursue the printing effect of bright colors and exquisite patterns, like offset printing process is more suitable, its dot resolution is high, the printing reproduction effect is good, can well present the fine line version of overprint or overprint and multi-color screen pattern, often used in the printing of color preprinted carton paper. If there are requirements for the three-dimensional effect and thickness of the pattern, gravure printing is a good choice. Its ink layer is relatively thick, the printed ink color is rich and three-dimensional, and the printing layers on the plate are rich and the texture is strong.?

?

- Consider cost factors: Cost is an important consideration when choosing a printing technology. If it is mass production, the traditional gray background with white characters printing process has a relatively low cost, and flexographic printing also has the characteristics of low cost and fast printing speed, making it suitable for large-scale orders. If it is a small-batch or specially customized product, digital printing is more cost-effective. It does not require plate-making and can reduce plate-making costs. For example, a small food company that needs to print a small number of different patterns on cartons every month, digital printing can effectively control costs.?

?

- Consider production efficiency: Production efficiency directly affects delivery time. The traditional gray background with white characters printing process and flexographic printing have a fast production speed and are suitable for large-scale production. However, high-end processes such as digital printing and screen printing have a relatively slow production speed and are suitable for small-batch or customized production. For instance, when e-commerce enterprises participate in large-scale promotional activities and need to complete a large number of the same carton printing within a short period of time, flexographic printing has more advantages than digital printing.?

?

- Consider the usage environment: If the product will encounter various complex environments during transportation and storage, an appropriate printing technology should be selected. For the need for waterproof, moisture-proof products, you can choose the laminated printing process, so that corrugated boxes have better waterproof performance; For products that need to be displayed or stored outdoors, you can choose a UV printing process to increase the weatherability of corrugated boxes.?

?

Comparison of the four printing technologies in all aspects

?

Carton printing is not merely about "printing patterns", but also a crucial step in brand communication, logistics protection and environmental compliance. With the explosion of e-commerce, the tightening of green policies (such as the new regulations on recycled labels in the European Union), and the increasing demands of customers for the appearance and differentiation of packaging, a single printing method is no longer sufficient to cover all scenarios. Mainstream technology in printing quality, speed, cost, base material between the minimum quantity for fitment, environmental protection and make trade-offs.