I. What is a corrugated box?

Corrugated carton is made of corrugated cardboard packaging containers, with the advantages of light, pressure, shock, moisture-proof.It is widely used in home appliances, electronics, food, medicine, chemical and other fields as the main container for product packaging and transportation.

?

The structure of corrugated boxes is usually made of paper, paper, core paper and corrugated paper sandwiching between them. This structure gives the carton excellent strength and stability.

?

?

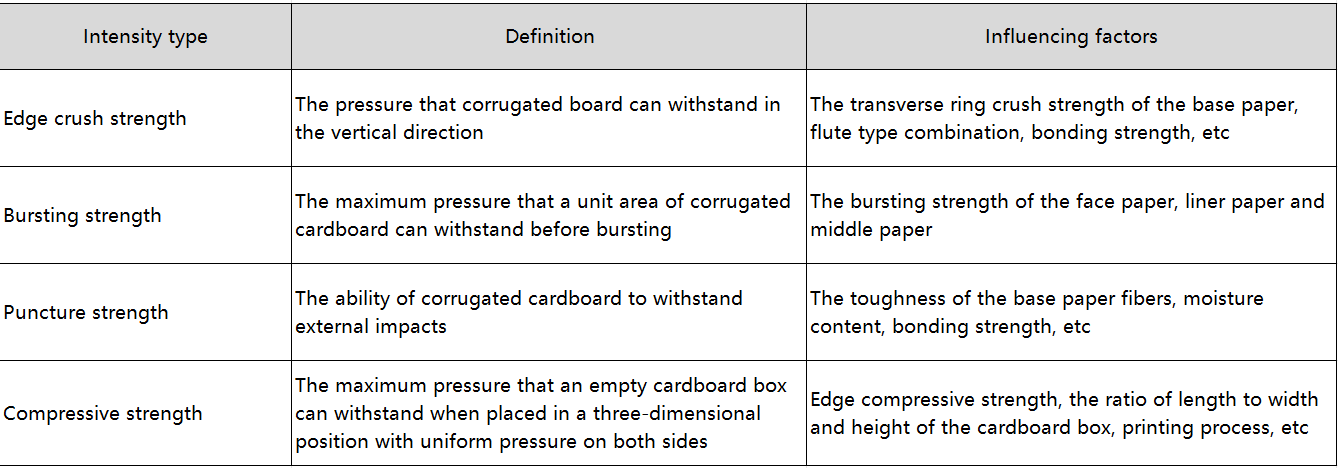

The strength of corrugated carton is a comprehensive index to measure its ability to withstand external pressure, impact and stacking. The core includes key parameters such as pressure resistance, breaking resistance and edge pressure, which directly affect the protection performance of packaging in transportation and storage.

?

II. Determinants of The Strength of Corrugated Boxes

Corrugated Cardboard Type

At present, there are five types of corrugated boxes A, B, C, E and K in common use, and the three types of corrugated boxes A, B, C and their combinations are the most commonly used in the production of corrugated boxes at home and abroad.Generally speaking, the larger the corrugated shape, the greater the compressive strength of the carton, but the greater the deformation;The smaller the corrugated type, the smaller the compressive strength of the carton, the smaller the deformation.For example, if the carton is too large and the corrugated shape is small, the carton will be easily crushed during the compression test;The carton is too small, the corrugated shape is very large, and the deformation will be too large when the compression test is carried out, and the buffer process is long.

?

Size of Cartons

- Perimeter: In the case of the same material and corrugated type, the growth of carton perimeter and the growth of compressive strength will form a changing curve.At the beginning, the longer the circumference of the carton, the higher the compressive strength. However, with the increase of the circumference of the carton, the instability of the carton is increased. After the circumference of the carton reaches a certain stage, the compressive strength that can withstand will show a certain proportion of the decline.

?

- Height: When the height is 100-350mm, the compressive strength decreases slightly with the increase of the height of the carton;When the height is between 350-650mm, the compressive strength of the carton is almost unchanged. When the height exceeds 650mm, the compressive strength of the carton decreases as the height increases.

?

- Aspect ratio: In general, the aspect ratio of the carton is in the range of 1-1.8, and the effect of the aspect ratio on the compressive strength is only ±5%.Among them, when the aspect ratio RL = 1.2-1.5, the compressive strength of the carton is the highest.When the aspect ratio of the carton is 2:1, its compressive strength decreases by about 20%, so when determining the size of the carton, the aspect ratio should not exceed 2, otherwise it will cause cost waste.

?

Thickness and Material of Cardboard

When the thickness of corrugated cardboard is the same, the higher the corrugated cardboard, the higher the compressive strength of the carton. When the thickness of the same type of

Corrugated Board varies, the greater the thickness, the higher the compressive strength of the corrugated box. In addition, different types of cardboard also affect the compressive strength of corrugated boxes. Generally speaking, the better the cardboard used, the higher the compressive strength of the corrugated box.

?

Other Factors

In addition to the above, the stacking time of the carton, the printing process, the temperature and humidity environment of the stacking, the drop impact and the vibration impact and other factors also have a great impact on the compressive strength of the carton, but these are often the most easily ignored when we choose the carton.

?

III. The Importance of Corrugated Box Strength

Protect the Product

The strength of corrugated cartons directly affects their functions in transportation, storage and goods protection, etc.If the compressive strength of the carton is too low, it may not be able to withstand the extrusion force, weight and other loads during transportation, resulting in damage to the cargo or worse.Therefore, it is important to properly assess the compressive strength of cartons to ensure that the product is adequately protected during transportation and storage.

?

Affect Transportation and Storage Efficiency

The strength of corrugated cartons is closely related to their performance during transportation and storage.Insufficient strength cartons may result in damaged goods in transit, increasing the risk of returns and losses, while also potentially impacting storage efficiency as damaged cartons may require additional handling and management.On the contrary, excessive intensity may bring unnecessary costs and logistical difficulties.Therefore, it is very important to design and manufacture corrugated boxes suitable for transportation, storage and protection of goods.

?

Cost-effectiveness

The strength of corrugated boxes is closely related to their cost effectiveness.Insufficient strength cartons may cause damage to the goods and increase additional costs. However, excessive intensity may bring about unnecessary costs.Therefore, choosing the right corrugated board and thickness, designing and manufacturing corrugated boxes suitable for the transportation, storage and protection of goods can ensure product safety while achieving cost-effective optimization.

?

Meet Industry Standards

The strength testing and evaluation of corrugated cartons is an important link to meet industry standards.For example, GB/T6543-2008 standards such as single corrugated boxes and double corrugated boxes for transport packaging have clear requirements for the compressive strength and other properties of corrugated boxes.Through the strength test, it can be ensured that the corrugated box meets the relevant standards, so as to ensure the quality and safety of the product.

?

?

A corrugated box with good strength and intact shape can leave a good first impression on customers.If customers receive goods with broken packaging, it will make them doubt the quality of the product and the brand.On the contrary, strong and durable cartons will make customers feel that the brand has taken care of the product and service, thus enhancing the image and reputation of the brand.

?

The strength of corrugated box is very important, which is directly related to the safety of the inner products in the whole logistics process.If the carton strength is not enough, it is prone to damage, deformation and other problems in the process of transportation and storage, resulting in product damage and affecting product quality and sales.Therefore, when choosing corrugated boxes, we must pay attention to their strength indicators to ensure that they can meet the transportation and storage needs of products. Shiteng is committed to providing comprehensive protection for your goods. If you need sturdy, durable and high-quality heavy-duty transport cartons, this is your ideal choice.