Box Divider Inserts: Guide to Best Storage Solutions

2025,11,04

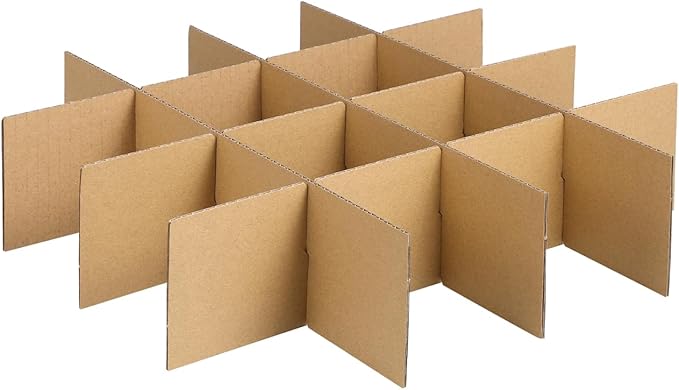

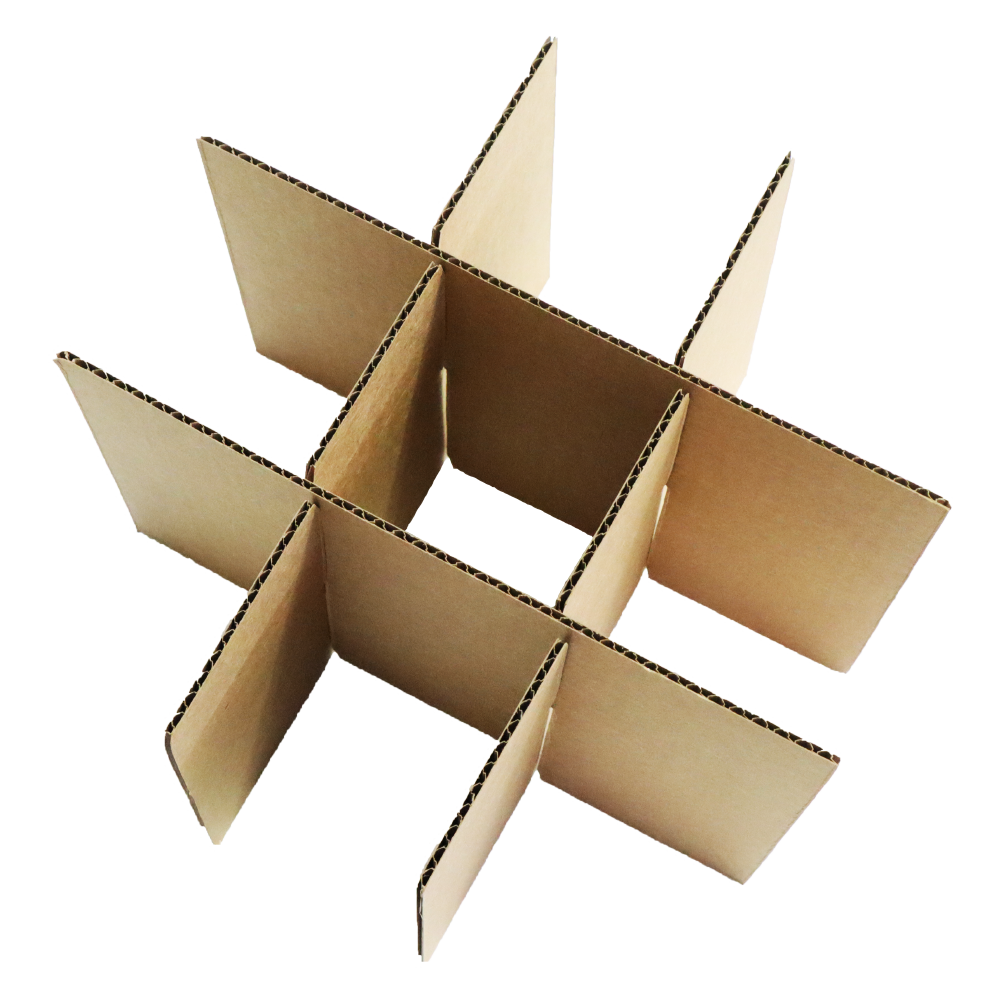

A paper box divider is a component used to separate the internal space of a paper box, which is usually made of paper or cardboard. It is inserted or fixed inside the box to realize the classification, positioning and protection of internal items.The design of the divider is diverse, which can be customized according to different needs to meet the packaging and storage needs of different products.

?

?

?

II. The Necessity of Box-type Separated Inserts

Protect product safety

- Anti-collision and wear:?The separator divides the inside of the box into independent Spaces to avoid friction and extrusion between items in transportation or movement.For example, Z-shaped origami partitions are often used to fix bottles and cans in Pharmaceutical Packaging boxes.

?

- Shock absorption: Some separators (such as paper trays) can absorb external forces through structural design, especially suitable for fragile items (such as glassware and electronic components).

?

Improve storage and usage efficiency

- Classification and arrangement: The orderly storage of items is realized by partitioning, such as the snack box with an integrated origami partition to separate different flavors of pastries, and the refrigerator partition to divide the food area.

?

- Space utilization optimization: Flexible adaptation of the internal structure of the box to avoid space waste, such as drawer storage divider can be freely combined and adjusted.

?

Enhance the aesthetics and value of packaging

- Regular display: The separator makes the products arranged neatly and improves the display effect, especially suitable for gift packaging (such as cigar boxes, cosmetics boxes).

?

- Brand image transmission: Customized divider design can reflect the ability to control brand details and enhance consumer trust in products.

?

III. Main Advantages of Box-type Separated Inserts

Environmental protection: degradable and sustainable

The environmental protection property of paper dividers is one of its most significant advantages, especially over non-degradable materials such as plastics:

?

- Natural degradation: Paper materials come from natural trees and can be degraded in a short time after being discarded, which will not cause long-term pollution to the environment and meet the requirements of sustainable development.

?

- Recyclable and renewable: Paper products can be recycled and remade into paper, reducing resource consumption and waste generation. In contrast, the recycling process for materials such as plastics and metals is more complex, and the cost of regeneration is higher.

?

- Non-toxic safety:?The paper material itself is non-toxic and tasteless, and will not release harmful substances. It is especially suitable for food, medicine and other fields with high health requirements, avoiding the possible migration risk of chemical substances from plastics.

?

Cost-effectiveness: Abundant raw materials and low processing costs

Compared with metal, plastic and other materials, paper dividers have more advantages in cost control:

?

- Extensive and cheap raw materials: The raw materials (trees) of paper products are abundant, and the collection and processing costs are low, while plastics rely on petrochemical raw materials, and metals are more affected by the price fluctuations of mineral resources.

?

- Convenient processing: Paper materials are easy to cut, fold and stamp into shape. They can be made into various shaped partition structures (such as Z-shaped, one-piece positioning paper trays, etc.) through simple processes, meeting different packaging needs. In contrast, metal processing requires welding and cutting, while plastic processing needs mold injection molding, which has higher process complexity and cost.

?

Functional adaptability: Buffer protection and customization

The suitability of paper separator in packaging function is outstanding, especially in light weight and buffer protection:

?

- Buffer and protection performance: Paper and cardboard have good buffer performance, can absorb the impact through its own structure (such as corrugated, folding design), effectively protect the internal items from collision damage, and both light shielding, moisture-proof, dustproof effect, compared with plastic, metal rigid protection, more suitable for fragile packaging.

?

- Customization flexibility: According to the size and shape of the product, flexible design of the separator structure (such as multi-grid partition, special-shaped cutting), to meet the classification and storage needs of different items, and the customization of metal and plastic separator needs to re-open the mold, long cycle and high cost.

?

- Lightweight: The density of paper material is low, which can reduce the overall packaging weight and reduce the cost of logistics and transportation, while the metal divider will increase the packaging weight. Although the plastic is light but has low strength, it may need a thicker structure design.

?

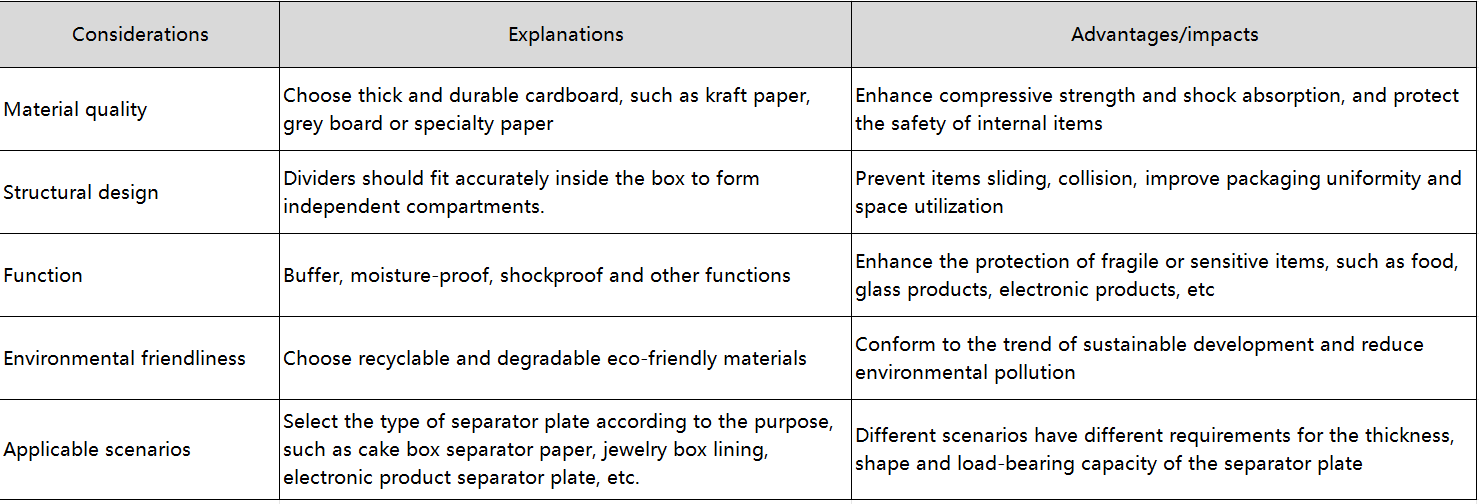

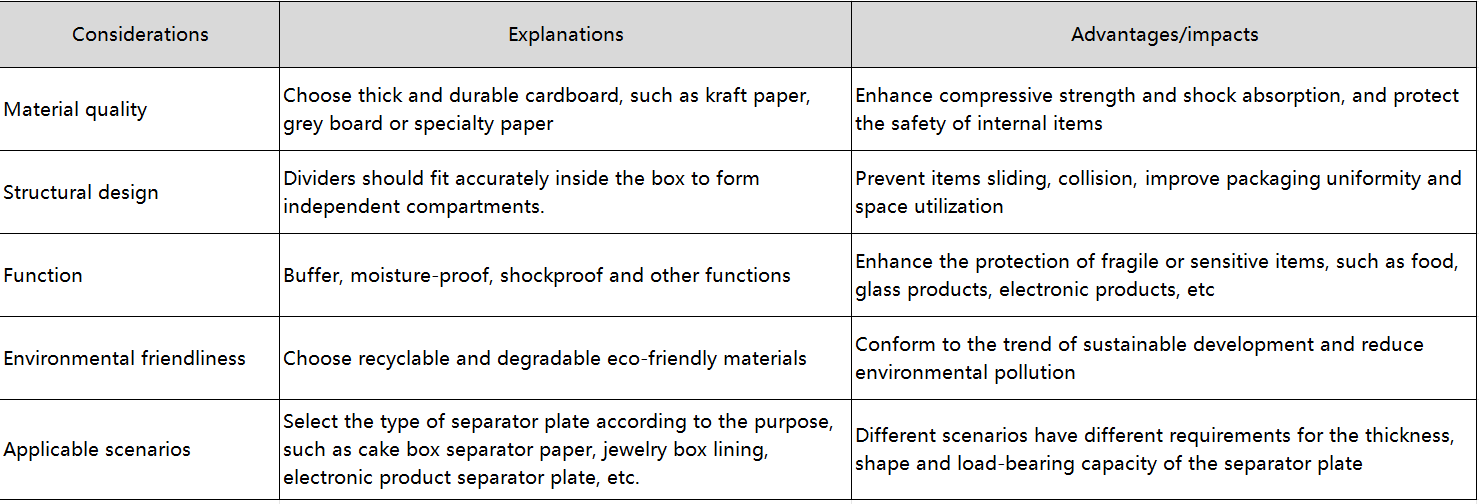

Factors to consider when choosing paper box separators

Factors to consider when choosing paper box separators ?

IV. Summary

Although the paper box divider is an auxiliary component, it has become a key element connecting product protection, user experience and brand image through the design thinking of "seeing the big from the small".The essence of its function is to use physical space division to realize the orderly management and value improvement of goods, and at the same time meet the needs of lightweight and green modern packaging.

Factors to consider when choosing paper box separators

Factors to consider when choosing paper box separators