Anti-static cartons are packaging containers with anti-static functions. They can effectively release the static charges accumulated on the surface of objects, prevent the accumulation of charges from generating high potential differences, and thus protect the items stored inside from static damage. It is widely used in industries sensitive to static electricity such as electronics, semiconductors, and precision instruments. It can be applied in the turnover, packaging, storage, and transportation of items, and is an important tool for realizing the generalization and integration of logistics containers in modern production management.

?

1. Product Overview

Size: 2 3?4 x 2 3?4 x 1"

Protect your smallest and most fragile components.

?

esd cardboard is made of

conductive corrugated cardboard. Anti-static conductive card-type component boxes are

a convenient and safe choice for storing and transporting electrostatic sensitive electronic components. The anti-static box is available in a variety of sizes to meet your needs and can be optionally equipped with pink anti-static protective foam to

help prevent components from being damaged by impact. According to your shipping requirements, these esd corrugated boxes can be delivered either in flat pack or fully assembled.

?

The conductive card component box adopts an anti-static conductive card coating, and the anti-static foam filled inside the box provides anti-static cushioning for your components. These esd corrugated boxes are available in assembly or flat packaging and can be customized according to your requirements.

?

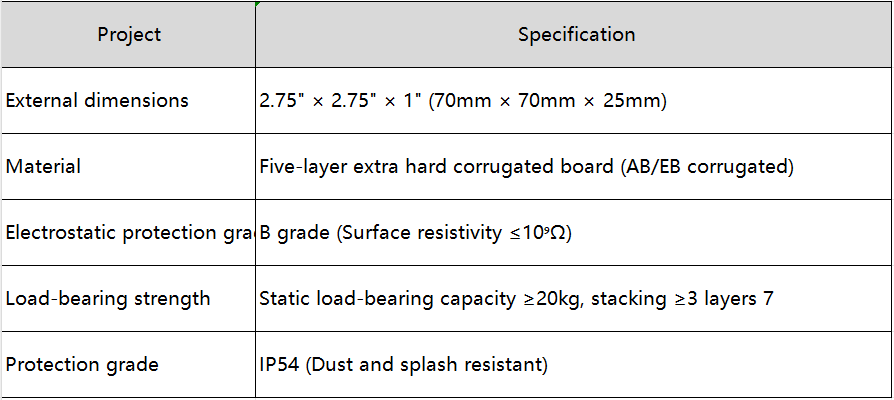

2. Core parameters

?

3. Product advantages

Environmental protection safety

esd corrugated box is made of recyclable corrugated paper and meets environmental protection standards. After moisture-proof treatment, it is not easy to deform in a humid environment.

?

Structural reliability

The Esd cardboard has a five-layer AB corrugated structure (face paper + core paper + backing paper), with edge and corner reinforcement design. Its compressive strength reaches 5.8KN/m2, which is superior to the requirements of industrial transportation.

Zero-error precision die-cutting process, suitable for the packaging of micro and small precision components, reducing internal shaking.